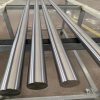

904L Stainless Steel Bar/Rod

904L stainless steel is a stainless steel material with good corrosion resistance, strength and mechanical properties. Given its excellent tolerance to harsh environments, 904L stainless steel bars are commonly used as manufacturing parts in fields including petroleum, chemical industry, and marine engineering.

Description

904L Stainless Steel Bar Description

904L stainless steel bars are made of a high-strength material. This high-strength characteristic allows the bars to show stable performance when subjected to high loads and stresses, and is not prone to deformation and fracture. Besides, good toughness and can help maintain stable performance in low temperature environments. More importantly, 904L stainless steel bars can maintain good durability and stability in friction and wear environments. This characteristic allows 904L stainless steel bars to have a long service life under mechanical movements and friction situations. Lastly, 904L stainless steel bars can maintain stable performance in various corrosive environments.

Product Parameters

| Product Name | 904L Stainless Steel Bar | |

| Type | Steel Bar | |

| Outer Diameter | Round Bar | 4mm-500mm |

| Hexagon Bar | 18mm-57mm (11/16″ to 2-3/4″) | |

| Square Bar | 18mm-47mm (11/16″ to 1-3/4″) | |

| Flat Steel | 1/2 “to 10”, Thickness: 2mm-150mm, Can provide customized | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Mattness Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Stainless steel bars are used in a variety of industries such as shipbuilding, Defense, Automotive, Textiles, Paper and pulp, Manufacturing, Cement, Heavy earthmoving equipment and construction, etc. | |

Chemical Composition

| C | Si | Mn | Cr | Ni | Mo | S | P |

| ≤ 0.02 | ≤1.0 | ≤ 2.0 | 19.0~23.0 | 23.0~28.0 | 4.0~5.0 | ≤ 0.035 | ≤ 0.045 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥490 | ≥220 | ≥35 | ≤ 90HRB |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 8.0 | 195 | 15.5 | 12.0 | 94 |