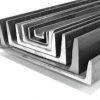

321 Stainless Steel Angle/Section

321 stainless steel sections, an austenitic chromium-nickel steel alloyed with titanium, are known for their excellent resistance to intergranular corrosion and stability in high-temperature environments. The addition of titanium limits chromium carbide formation, enhancing high-temperature strength. These sections are ideal for applications involving intermittent heating within the carbide precipitation range, up to 900°C. Common uses include aerospace components, exhaust manifolds, heat exchangers, and expansion joints. They are also favored in the chemical processing industry. 321’s resistance to temperature-induced corrosion and overall durability make it suitable for various demanding industrial applications, especially where weldability and strength are crucial at high temperatures.

Description

| Name | Stainless Steel Angle/Section | |||

| Technique | CR/HR | |||

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. | |||

| Steel Grade | 201;301;304;310S;316;321;430;2205;2507;904,etc. | |||

| Tolerance | +/-0.01-1.0% | |||

| Length | Customization | |||

| Thickness | 0.4-30mm / Customized | |||

| Service | OEM, Customized Processing Service | |||

| Processing Type | Cutting,Bending,Machining,Fabrication | |||

CHEMICAL COMPOSITION:

| Grade | C | Si | Mn | p | S | Ni | Cr | Mo | N |

| 201 | ≤0 .15 | ≤0.8 | ≤1.0 | ≤0.04 | ≤ 0.03 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | 0.18-0.20 |

| 904L | ≤0 .02 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.035 | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 | ≤0.1 |

| 654SMO | ≤0 .02 | ≤0 .5 | 2.0-4.0 | ≤0.03 | ≤0.005 | 21.0-23.0 | 24.0-25.0 | 7.0-8.0 | 0.45-0.55 |

| 253MA | 0.05-0.1 | 1.4-2.0 | – | ≤0.045 | ≤ 0.03 | 10.0-12.0 | 20.0-22.0 | – | 0.14-0.20 |

| AL-6XN | ≤0 .02 | ≤1.0 | ≤2.0 | ≤0.04 | ≤ 0.01 | 23.5-25.5 | 20.0-22.0 | 6.0-7.0 | 0.18-0.25 |

| 304 | ≤0 .08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | – | – |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | – | – |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | – | – |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | – | – |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | – |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 16.0 -18.0 | 2.0 -3.0 | – |

| S32760 | ≤ 0 .03 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.015 | 6.0-8.0 | 24.0 -26.0 | 3.0-4.0 | 0.2-0.3 |

| S32750 | ≤ 0 .03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 2.0-3.0 | 0.24-0.32 |