-

321 stainless steel sections, an austenitic chromium-nickel steel alloyed with titanium, are known for their excellent resistance to intergranular corrosion and stability in high-temperature environments. The addition of titanium limits chromium carbide formation, enhancing high-temperature strength. These sections are ideal for applications involving intermittent heating within the carbide precipitation range, up to 900°C. Common uses include aerospace components, exhaust manifolds, heat exchangers, and expansion joints. They are also favored in the chemical processing industry. 321’s resistance to temperature-induced corrosion and overall durability make it suitable for various demanding industrial applications, especially where weldability and strength are crucial at high temperatures.

321 stainless steel sections, an austenitic chromium-nickel steel alloyed with titanium, are known for their excellent resistance to intergranular corrosion and stability in high-temperature environments. The addition of titanium limits chromium carbide formation, enhancing high-temperature strength. These sections are ideal for applications involving intermittent heating within the carbide precipitation range, up to 900°C. Common uses include aerospace components, exhaust manifolds, heat exchangers, and expansion joints. They are also favored in the chemical processing industry. 321’s resistance to temperature-induced corrosion and overall durability make it suitable for various demanding industrial applications, especially where weldability and strength are crucial at high temperatures. -

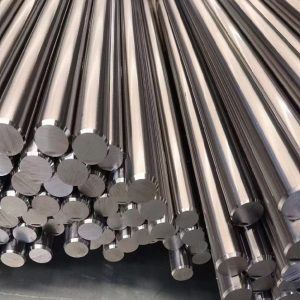

321 Stainless Steel Bar/Rod

321 stainless steel is an austenitic stainless steel characterized by excellent corrosion resistance at room temperature, as well as good high-temperature strength and creep resistance.

-

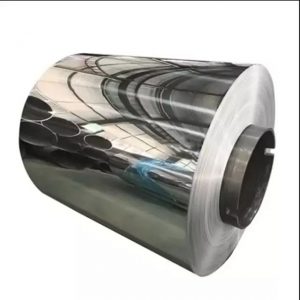

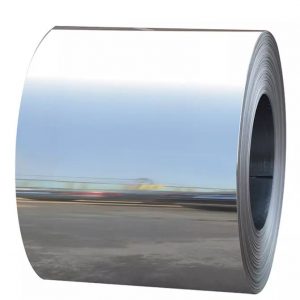

321 Stainless Steel Coil/Strip

321 stainless steel is an austenitic stainless steel of excellent corrosion resistance at room temperature, as well as good high-temperature strength and creep resistance.

-

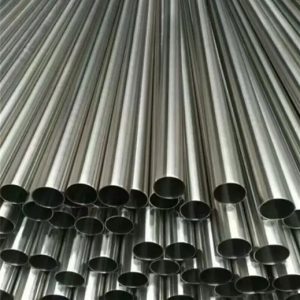

321 Stainless Steel Pipe/Tube

321 stainless steel is an austenitic stainless steel that has excellent corrosion resistance at room temperature, aside from high-temperature strength and creep resistance.

-

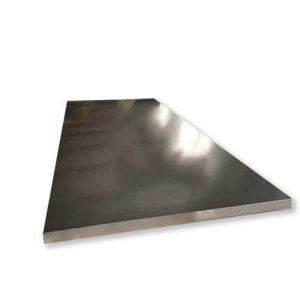

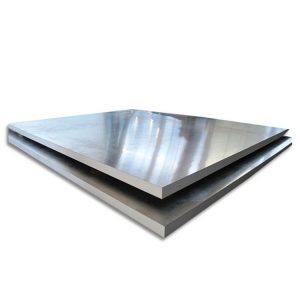

321 Stainless Steel Plate/Sheet

321 stainless steel is an austenitic chromium-nickel steel alloyed with titanium, which enhances its resistance to intergranular corrosion. It maintains stability in chromium carbide forming conditions, such as prolonged exposure to high temperatures. Resistant to scaling and oxidation in environments up to 900°C, 321 stainless steel is ideal for applications with intermittent heating within the carbide precipitation range. Commonly used in aerospace components, exhaust manifolds, heat exchangers, and expansion joints, this grade is also favored in the chemical processing industry. 321’s resistance to high-temperature corrosion and its overall durability make it well-suited for challenging industrial uses.

-

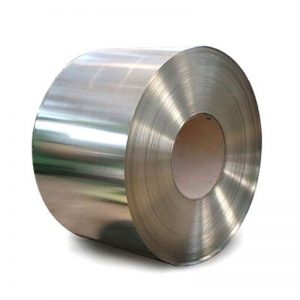

410 Stainless Steel Coil/Strip

410 stainless steel is a commonly used martensitic stainless steel whose main components are iron, carbon, chromium and a small amount of other elements.

-

416 Stainless Steel Coil/Strip

416 stainless steel coil has a chemical composition primarily including iron, chromium, nickel and other elements. 416 stainless steel has excellent corrosion resistance and mechanical properties because of this composition.

-

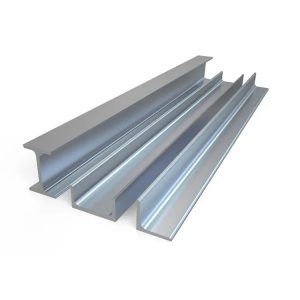

430 Stainless Steel Angle/Section

430 stainless steel U-channel is a ferritic, low carbon stainless steel known for its good corrosion resistance and formability, along with its magnetic properties. It contains a high amount of chromium, providing decent resistance to atmospheric corrosion and moderate resistance against many acids and bases. 430 U-channel is often used in consumer appliances, automotive trim, interior architecture, and components requiring magnetic properties. It’s also suitable for certain chemical applications due to its resistance to nitric acid and organic acids. This grade is popular in applications where moderate corrosion resistance, formability, and aesthetic appeal are required. -

430 Stainless Steel Bar/Rod

430 stainless steel has always been a popular material for a variety of applications for its durability and corrosion resistance. However, welding 430 stainless steel can be challenging due to its high chromium content.

-

430 Stainless Steel Coil/Strip

430 stainless steel is a popular material for a variety of applications for its durability and corrosion resistance. However, welding 430 stainless steel can be challenging with its high chromium content.

-

430 Stainless Steel Pipe/Tube

430 stainless steel is a very practical material for a variety of applications due to its durability and corrosion resistance. However, high chromium content makes it more difficult to perform welding jobs for 430 stainless steel.

-

430 Stainless Steel Plate/Sheet

430 stainless steel is a ferritic, low carbon stainless steel with good corrosion resistance and formability, coupled with useful mechanical properties. Its chromium content provides resistance to atmospheric corrosion and moderate resistance against many acids and bases. It is magnetic and has moderate thermal expansion. 430 stainless steel is often used in automotive trim, interior architecture, household appliances, and fuel burner parts. Due to its resistance to nitric acid and organic acids, it’s also used in certain chemical applications. This grade is known for its aesthetic appeal, making it a popular choice for visually exposed applications where corrosion resistance and formability are essential.

-

430 Stainless Steel Wire

430 stainless steel wire is a ferritic, low carbon stainless steel known for its good corrosion resistance and formability, along with magnetic properties. It contains high chromium, providing decent resistance to atmospheric corrosion and moderate resistance against many acids and bases. Its magnetic quality and moderate thermal expansion make it suitable for various applications. 430 wire is often used in consumer appliances, automotive trim, interior architecture, and in components requiring magnetic properties. Additionally, it’s used in certain chemical applications due to its resistance to nitric acid and organic acids. This grade is popular in applications where moderate corrosion resistance and formability are required, along with aesthetic appeal. -

904/904L Stainless Steel Plate/Sheet

904L stainless steel is a high-alloy austenitic stainless steel with a high nickel and chromium content, offering excellent corrosion resistance in various environments. Known for its resistance to pitting and stress corrosion cracking, it also contains additions of copper and molybdenum for enhanced corrosion resistance, particularly in sulfuric and phosphoric acid conditions. 904L is highly weldable and formable, making it suitable for severe corrosive environments like chemical processing, oil and gas exploration, pollution control equipment, and seawater equipment. Its superior corrosion resistance also makes it ideal for pharmaceutical and food processing applications where high sanitation standards are required.

-

904L Stainless Steel Angle/Section

904L stainless steel H-beam is a high-alloy austenitic stainless steel characterized by its high chromium, molybdenum, and nickel content, offering exceptional corrosion resistance, especially in harsh environments. This grade is particularly resistant to chloride attacks and sulfuric acid, making it suitable for severe chemical processing environments. 904L H-beam exhibits excellent weldability and formability. It’s extensively used in the chemical industry, particularly in sulfuric and phosphoric acid settings, oil and gas exploration equipment, pollution control devices, and in seawater cooling systems. Its superior corrosion resistance and robust mechanical properties make 904L H-beam ideal for demanding applications in corrosive conditions. -

904L Stainless Steel Bar/Rod

904L stainless steel is a stainless steel material with good corrosion resistance, strength and mechanical properties. Given its excellent tolerance to harsh environments, 904L stainless steel bars are commonly used as manufacturing parts in fields including petroleum, chemical industry, and marine engineering.

End of content

End of content