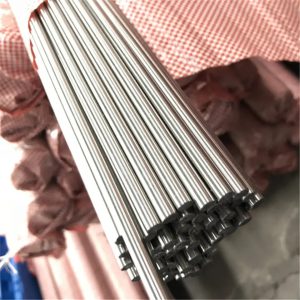

304 Stainless Steel Bar/Rod

304 stainless steel, as one of the most commonly used types of stainless steel, is an outstanding material when it comes to corrosion resistance, heat resistance, low temperature strength and mechanical properties. In addition, it has exceptional hot-workability so it leaves no heat treatment hardening phenomenon.