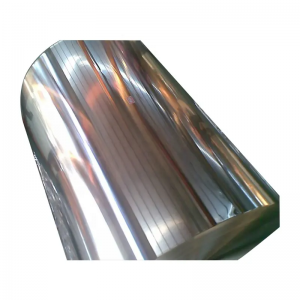

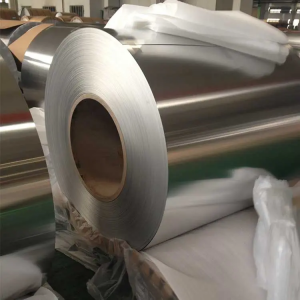

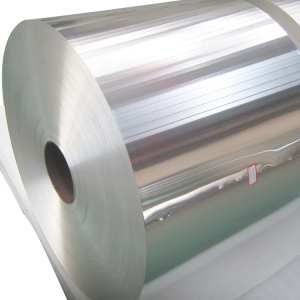

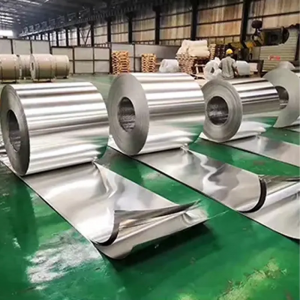

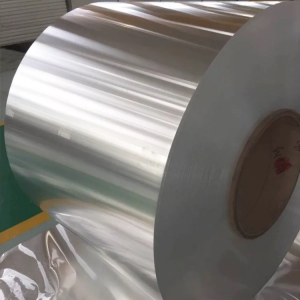

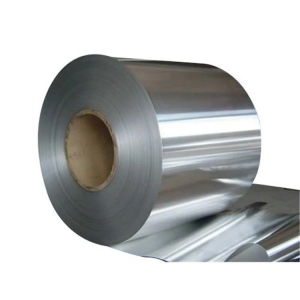

5005 Aluminum Foil

5005 aluminum foil is made of a multifunctional alloy with a wide range of properties and uses. It has excellent corrosion resistance, excellent weldability, good formability and machinability, and medium strength. This coil is used in many industries and applications.