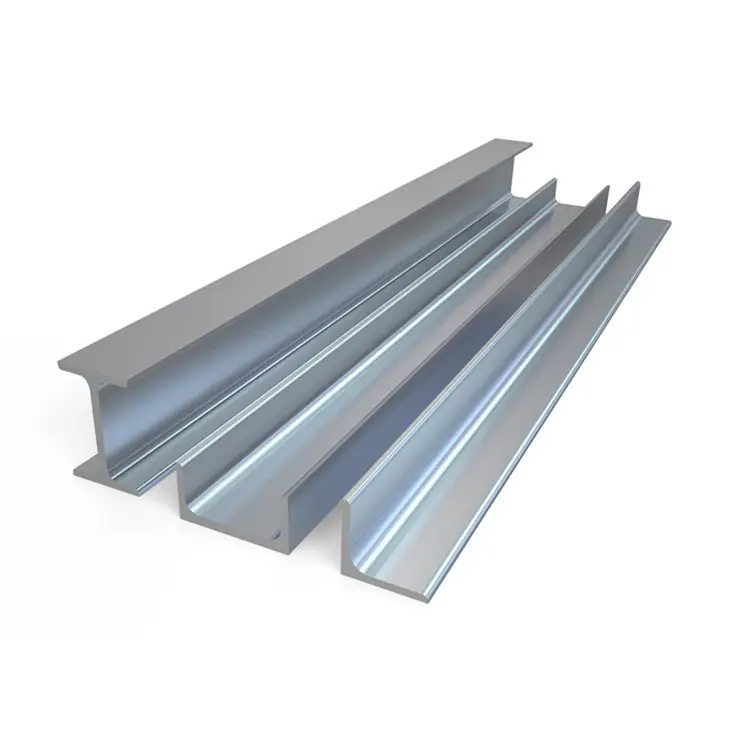

430 Stainless Steel Angle/Section

430 stainless steel U-channel is a ferritic, low carbon stainless steel known for its good corrosion resistance and formability, along with its magnetic properties. It contains a high amount of chromium, providing decent resistance to atmospheric corrosion and moderate resistance against many acids and bases. 430 U-channel is often used in consumer appliances, automotive trim, interior architecture, and components requiring magnetic properties. It’s also suitable for certain chemical applications due to its resistance to nitric acid and organic acids. This grade is popular in applications where moderate corrosion resistance, formability, and aesthetic appeal are required.

Description

| Name | Stainless Steel Angle/Section | |||

| Technique | CR/HR | |||

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. | |||

| Steel Grade | 201;301;304;310S;316;321;430;2205;2507;904,etc. | |||

| Tolerance | +/-0.01-1.0% | |||

| Length | Customization | |||

| Thickness | 0.4-30mm / Customized | |||

| Service | OEM, Customized Processing Service | |||

| Processing Type | Cutting,Bending,Machining,Fabrication | |||

CHEMICAL COMPOSITION:

| Grade | C | Si | Mn | p | S | Ni | Cr | Mo | N |

| 201 | ≤0 .15 | ≤0.8 | ≤1.0 | ≤0.04 | ≤ 0.03 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | 0.18-0.20 |

| 904L | ≤0 .02 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.035 | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 | ≤0.1 |

| 654SMO | ≤0 .02 | ≤0 .5 | 2.0-4.0 | ≤0.03 | ≤0.005 | 21.0-23.0 | 24.0-25.0 | 7.0-8.0 | 0.45-0.55 |

| 253MA | 0.05-0.1 | 1.4-2.0 | – | ≤0.045 | ≤ 0.03 | 10.0-12.0 | 20.0-22.0 | – | 0.14-0.20 |

| AL-6XN | ≤0 .02 | ≤1.0 | ≤2.0 | ≤0.04 | ≤ 0.01 | 23.5-25.5 | 20.0-22.0 | 6.0-7.0 | 0.18-0.25 |

| 304 | ≤0 .08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | – | – |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | – | – |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | – | – |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | – | – |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | – |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 16.0 -18.0 | 2.0 -3.0 | – |

| S32760 | ≤ 0 .03 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.015 | 6.0-8.0 | 24.0 -26.0 | 3.0-4.0 | 0.2-0.3 |

| S32750 | ≤ 0 .03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 2.0-3.0 | 0.24-0.32 |