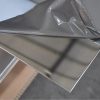

430 Stainless Steel Plate/Sheet

430 stainless steel is a ferritic, low carbon stainless steel with good corrosion resistance and formability, coupled with useful mechanical properties. Its chromium content provides resistance to atmospheric corrosion and moderate resistance against many acids and bases. It is magnetic and has moderate thermal expansion. 430 stainless steel is often used in automotive trim, interior architecture, household appliances, and fuel burner parts. Due to its resistance to nitric acid and organic acids, it’s also used in certain chemical applications. This grade is known for its aesthetic appeal, making it a popular choice for visually exposed applications where corrosion resistance and formability are essential.

Description

| Commodity | stainless steel plate sheet |

| Grade | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,420,430,etc |

| Brand | TISCO ,BAO STEEL,POSCO,JISCO,LISCO |

| Certification | ISO,SGS,BV |

| Thickness | 0.3mm-60mm |

| Width | 1000mm,1219mm(4feet),1250mm,1500mm,1524mm(5feet), |

| 1800mm,2200mm or as your requirements | |

| Length | 2000mm,2440mm(8feet),2500mm,3000mm,3048mm(10feet) |

| 5800mm, 6000mm or as your requirements | |

| Surface | NO.1, NO.2D, NO.2B, BA,NO.3, NO.4,NO.240,NO.400,Hairline,NO.8,Brushed |

| Standard | ASTM,AISI,SUS,JIS,EN,DIN,BS,GB,etc |

| Delivery time | 5 days after confirming the order |

| MOQ | 1 ton |

| Package | Stainless steel sheet packing:Waterproof paper + Metal Pallet or as per customers’ requirements. The inner size of container is below: |

| 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM,23MTS | |

| 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM,27MTS | |

| 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM,27MTS | |

| Payment term | L/C at sight or 30% TT as deposit and the balance paid against copy of B/L |

| Applications | architectural decoration, luxury doors, elevators decorating, metal tank shell, ship building, decorated inside the train, as well as outdoor works, advertising nameplate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others. |

| Advantages | Showing the splendor of your quality, wear-resistant as well, strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

Heat Treatment

Annealing: Anneal at 1850 – 1950 °F (1010 – 1066 °C), then water quench or rapidly air cool.

The annealing temperature should be kept as low as possible, consistent with the desired properties, because Type 201 tends to scale more than Type 301

Table 1 – Typical Mechanical Properties*

| UTS ksi (MPa) | 0.2% YS ksi (MPa) | Elongation % in 2″ (50.8 mm) | Hardness Rockwell |

| 110 (758) | 52 (360) | 55 | B87 |

*Annealed condition

Table 2 – Impact Strength

| Izod V-Notch Rockwell ft·lbs. (J) | 120 (163) |

Table 3 – Cold-Worked Properties*

| Condition | UTS ksi (MPa) min. | 0.2% YS ksi (MPa) min. | Elongation % in 2″ (50.8 mm) | Elongation % in 2″ (50.8 mm) | |

| < 0.015 in. | ≥ 0.015 in. | ||||

| 1/4 hard | 125 (862) | 75 (517) | 25 | 25 | 30 |

| 1/2 hard | 150 (1034) | 110 (150) | 15 | 18 | 35 |

| 3/4 hard | 175 (1207) | 135 (931) | 10 | 12 | 37 |

| Full hard | 185 (1276) | 140 (965) | 8 | 9 | 41 |

*Standard practice is to produce to either minimum tensile strength, minimum yield strength or minimum hardness, but not to combinations of these properties.